|

ITubing seamless stainless steel tubing can sustain high temperatures and pressures in the most challenging environments.

Product safety and accuracy are imperative in the aerospace and defense industries. We test our products according to strict industry and MIL-spec procedures to determine chemical composition, mechanical properties, defects and susceptibility to corrosion.

Specific Applications are:

|

|

Airframes

ITubing product is used in the mechanical structure of an aircraft. These applications can include the fuselage, wings and undercarriage. Proper materials, design and construction of these aircraft components enhance the aerodynamics and manufacturing methods required to achieve balance of performance, reliability and cost.

|

|

|

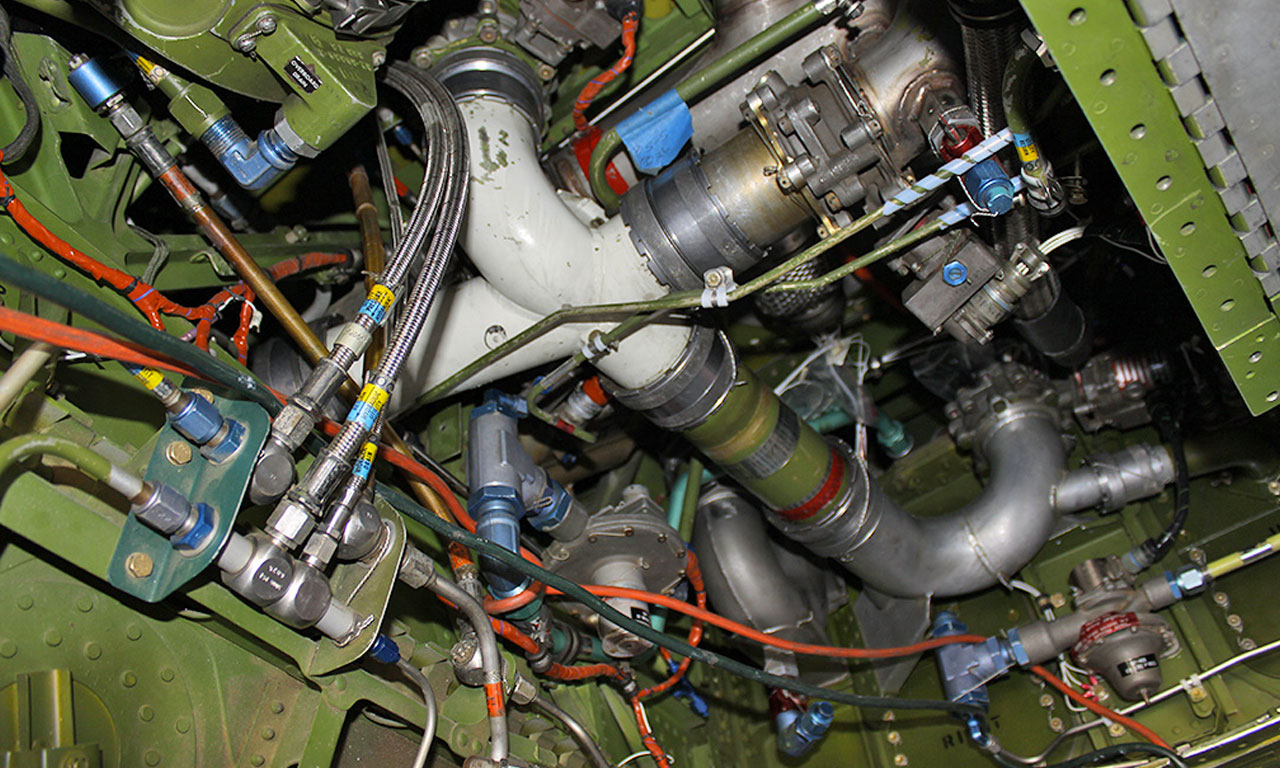

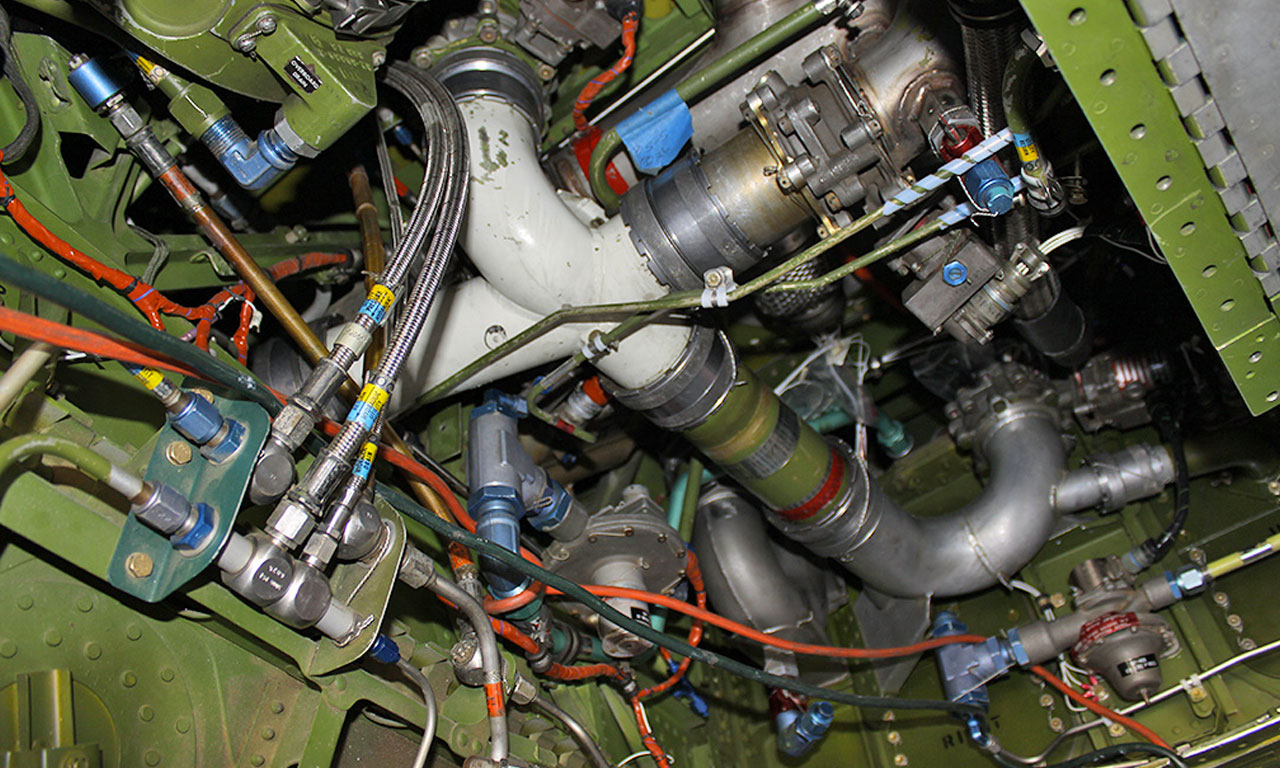

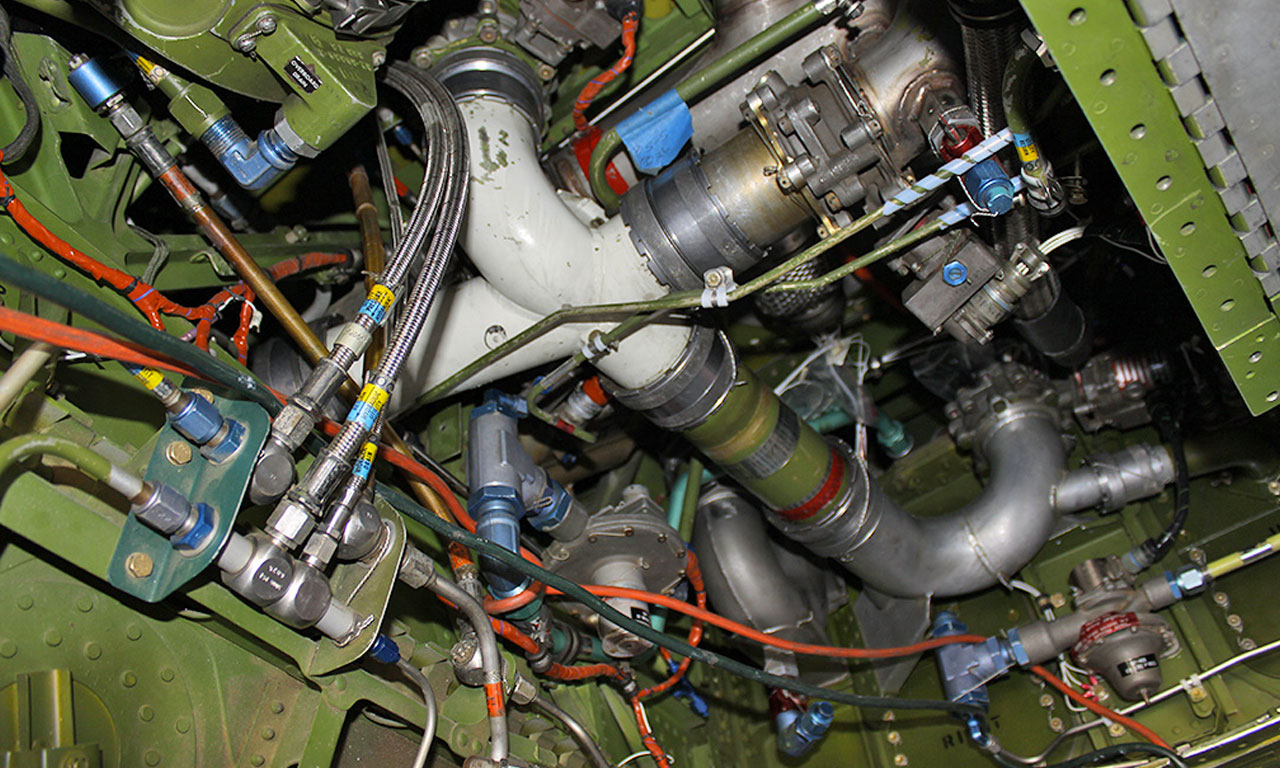

Fuel Lines

Stainless steel tubing is widely used in aircraft for fuel, oil, coolant, oxygen, instrument and hydraulic lines. This tubing is typically corrosion resistant 304 or 321 stainless steel and is frequently used in high pressure aircraft hydraulic systems of 3,000 psi or more.

|

|

|

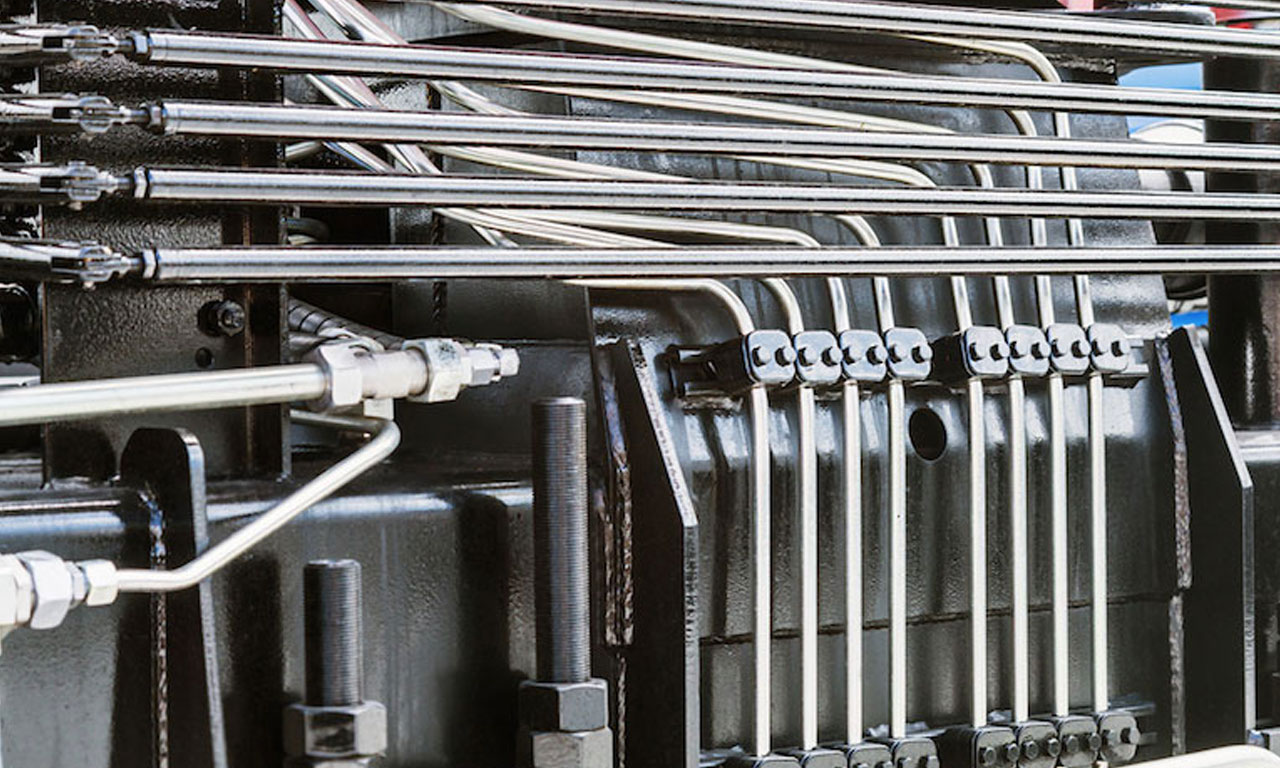

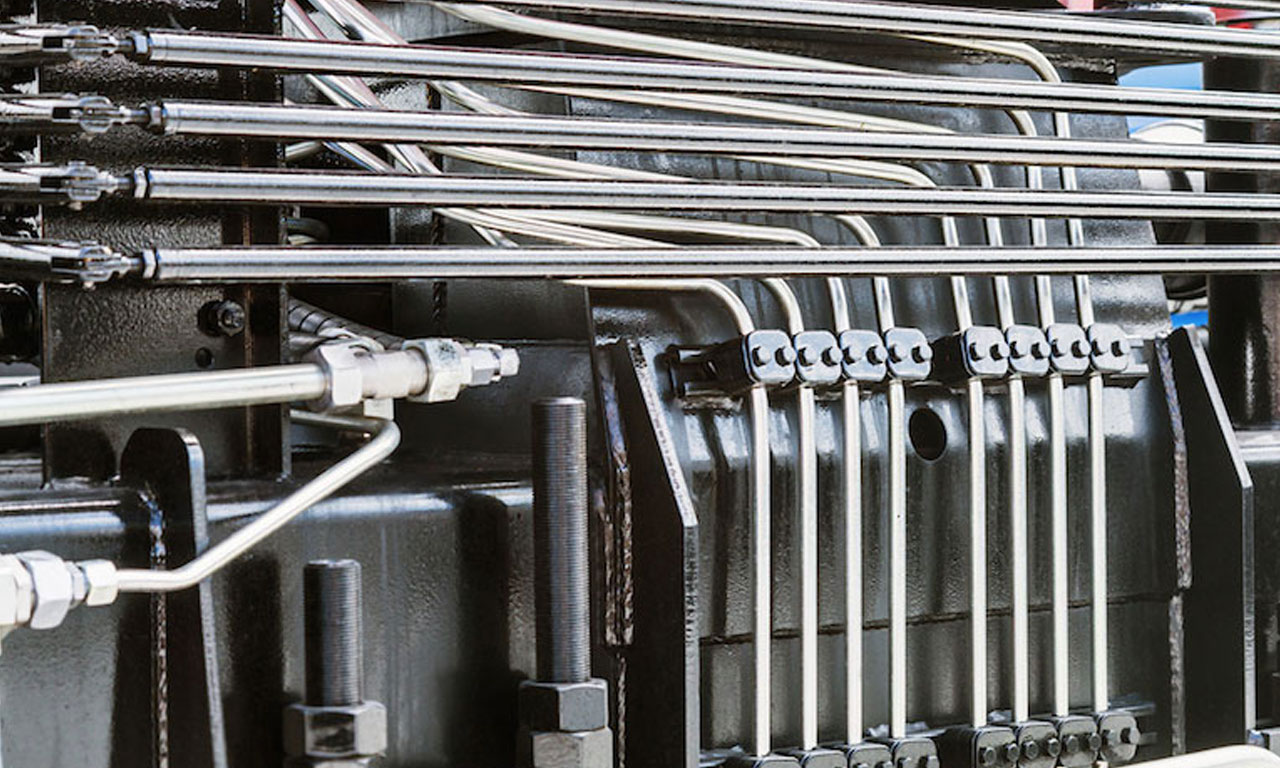

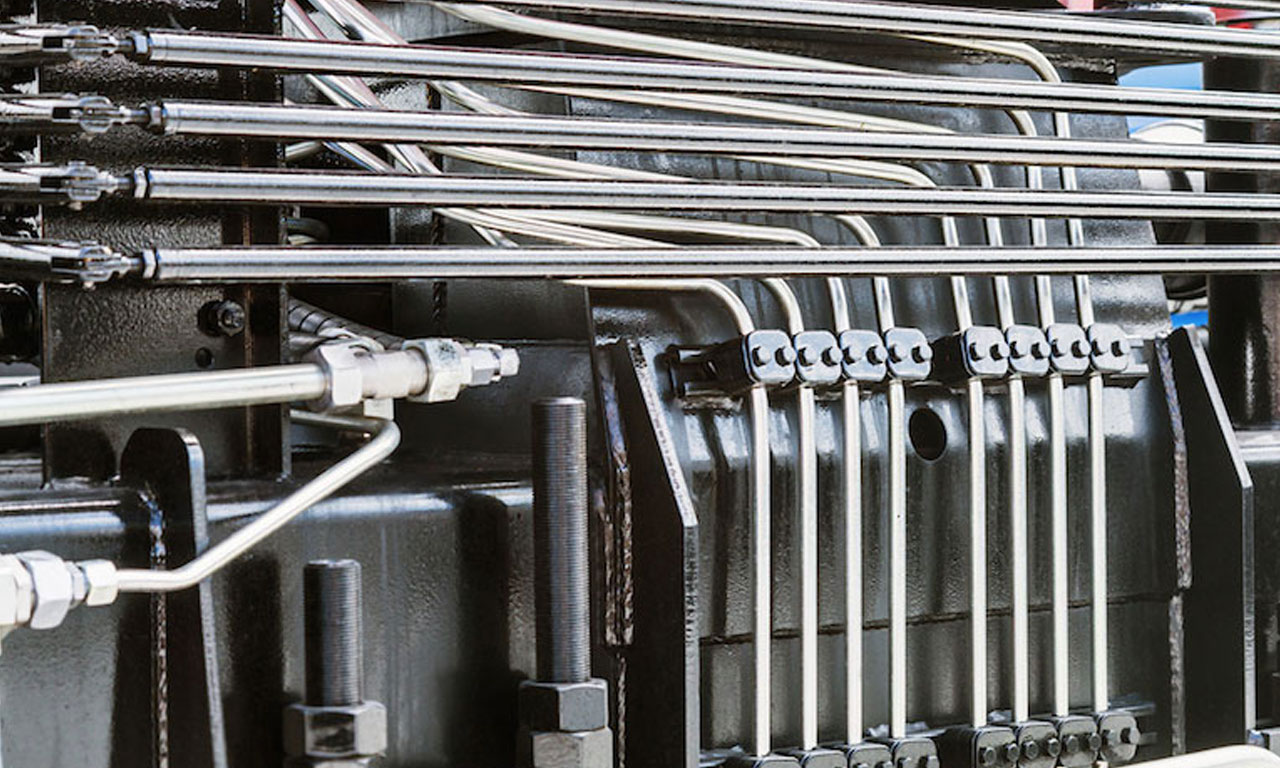

Hydraulic Lines

Many standard and custom aerospace stainless steel hydraulic tubing applications require seamless high pressure tube where the use of welded tube is discouraged because the potential for defects. Major uses include the operation of breaks, flaps, landing gear and throughout fire zones. The high tensile strength of this tubing allows for thinner walled, critical light weight construction. Stainless steel hydraulic lines are extremely important areas where there is a high risk of foreign object damage such as in landing gear and wheel well areas

|

|